Tailored measurement and control technology with user-friendly visualization

We plan the control system for your plant specially tailored to your requirements. We deliver all the control units to the construction site completely wired, including the measurement technology, control cabinets, and visualization. Only the external cable connections have to be made on site.

Control technology

Our control technology is the shared control center of the aeration system. Temperatures of the temperature monitoring system are read automatically, and the aeration time is individually controlled for each compost windrow depending on the specific process. A touch panel enables easy operation and parameter adjustment. In addition, the control technology is directly connected to visualization software. Changes of parameters are adopted in both systems. The compost control system is delivered as a pre-installed and pre-wired unit (IPC control, touch panel, motor protection switch, control cabinet, etc.).

Measurement technology

A failsafe ICA system is indispensable for economical and low-emission plant operation. For this reason, in order to record and control the process, we resort to tried-and-tested measurement technology that we supply in a technology package.

Depending on the plant section, we offer various sensors for temperature and pressure, as well as for air flow, filling level, and pH value to allow the monitoring of operating conditions. Our expertise and the interaction of these sensors make low-emission operation possible.

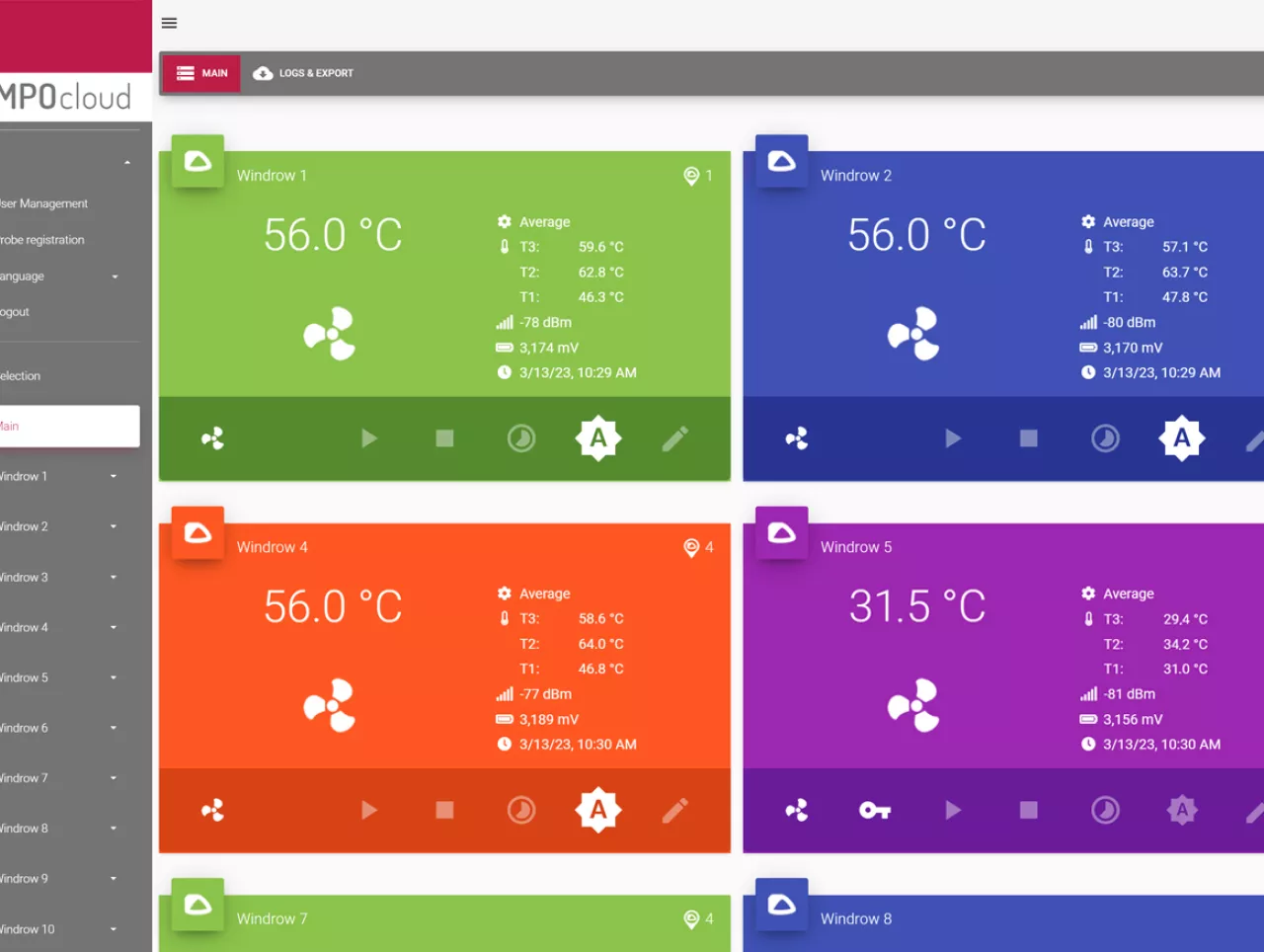

VISU

In order to achieve a simple understanding of the composting process, it must be represented in a clear and understandable way. The visualization is adapted to the needs of your plant and delivered completely pre-installed on the PC. Our visualization software allows easy handling and operation based on our experience in the visualization of numerous plants. Proof of sanitization, fluctuations in the process temperature, etc. can be monitored in a simple and clear way. You can make quick inputs of and changes to process parameters by a simple click of the mouse.

Control unit

The control technology can be delivered to the construction site completely pre-assembled as a plug-and-play solution in the form of a COMPOtainer. It can also accommodate the pre-wired COMPOair blowers in a separate room.

This ensures a dust-free and air-conditioned environment for the sensitive electronics. The touch panel allows the plant to be operated directly in this control center or via a connected remote PC preferably installed in the plant office. The two interfaces are identical and provide up-to-date plant information, measured values or alarms at all times.

Our cloud solutions

For mobile and cost-efficient monitoring, control and management of composting plants and container solutions, we recommend our cloud platform.

As a typical cloud solution, your data is no longer stored locally on your hardware, but virtually on a server. Any internet-enabled device can access it at any time and by several people, for example to control the temperature, irrigation or ventilation. According to the philosophy “don’t buy, just pay for use”, you no longer invest in hardware, you are always up-to-date, and you only pay for the ongoing use. The data can be further processed via a standard import into MS Excel.